INSERT ID | DRILLING AND DOWEL INSERTION

INSERT ID | DRILLING AND DOWEL INSERTION

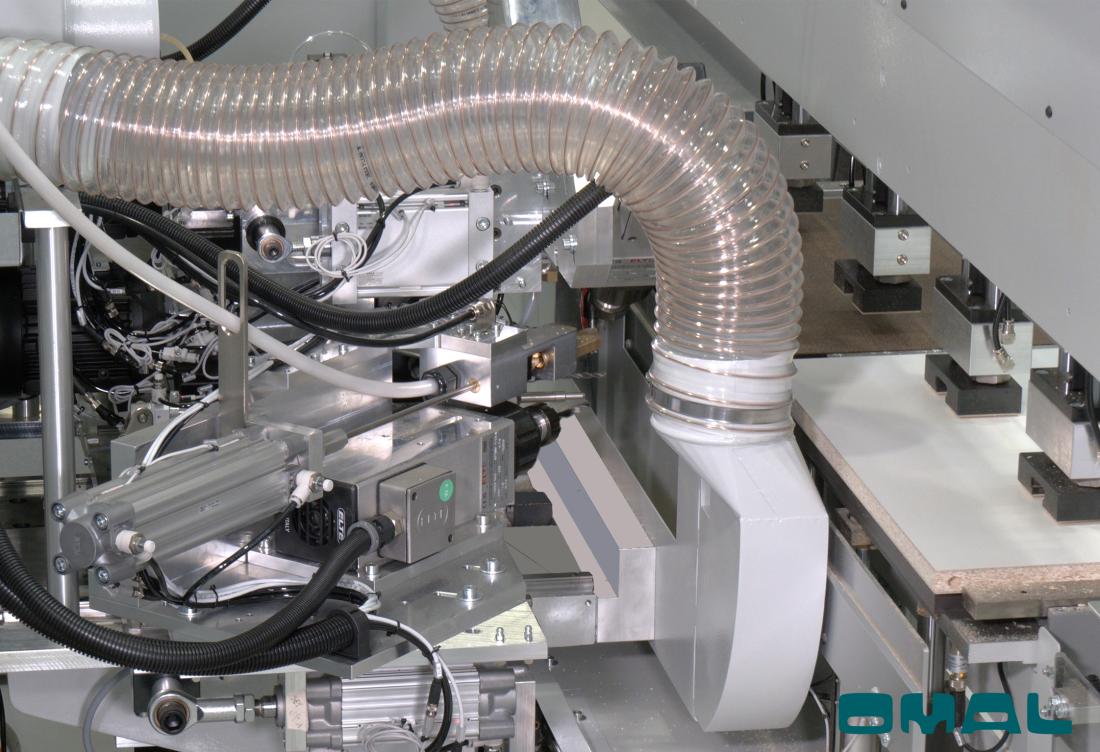

OMAL HORIZONTAL AND VERTICAL INCLINED BORE AND DOWEL MACHINE FOR VALINGE PINLOCK SYSTEMINSERT ID | DRILLING AND DOWEL INSERTION - Description:

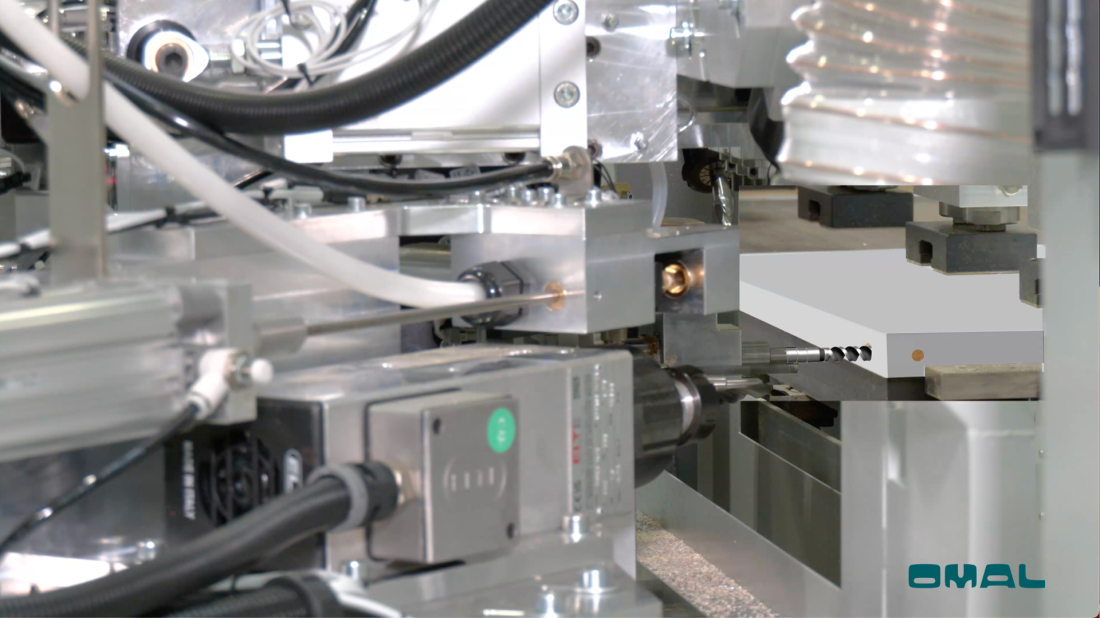

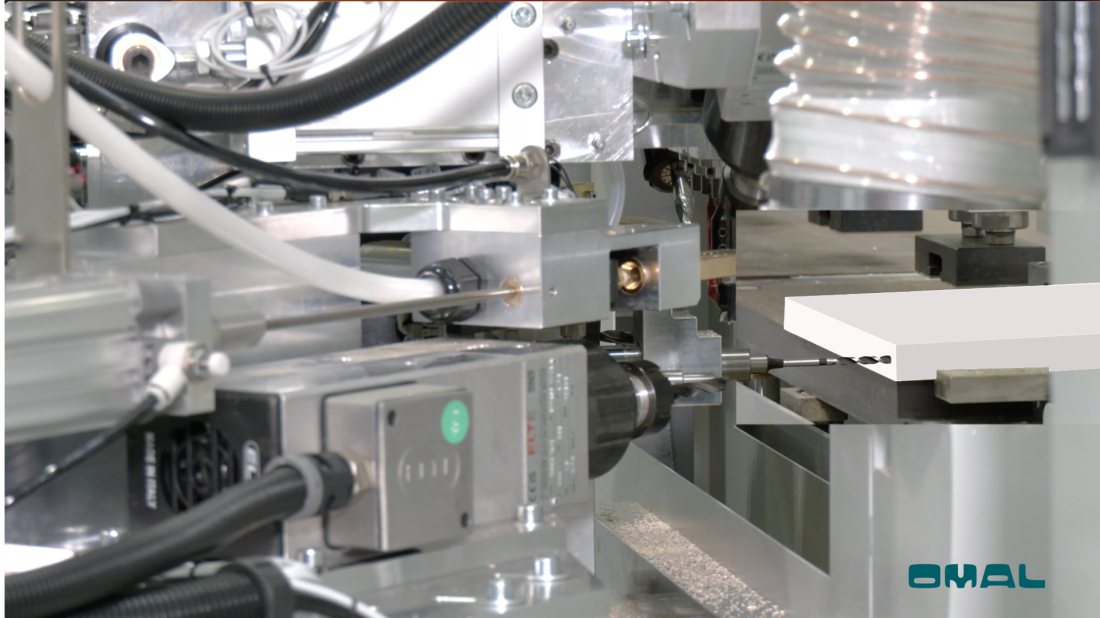

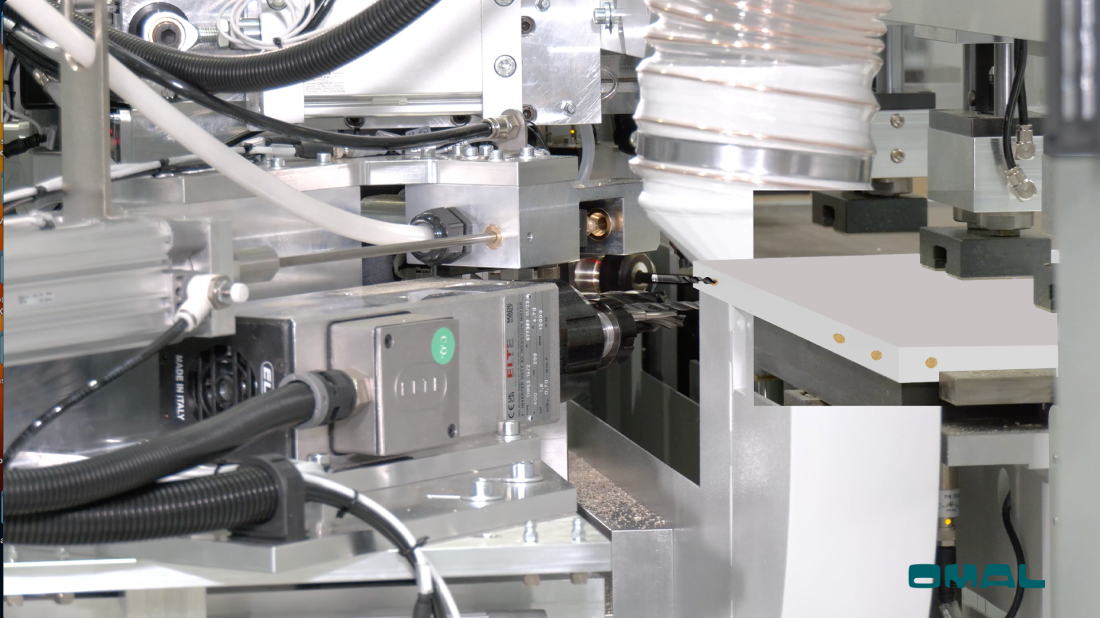

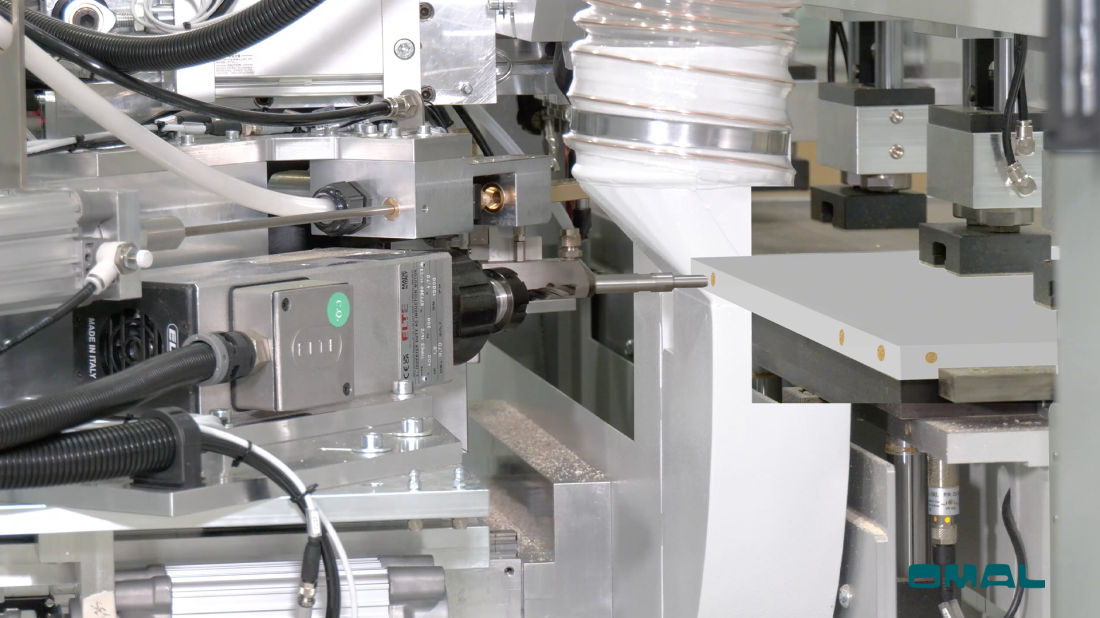

The INSERT ID is a CNC solution specifically designed for panel processing with the Valinge Pinlock system. The machine features a full PC interface with a working field of 1300 mm or 2500 mm, divided into zones for pendulum processing, and comes standard with four reference stops.

Machine Functions:

- Horizontal drilling and inclined insertion (42–45°) of wooden dowels in both directions.

- Horizontal drilling for the Pinlock system.

- Vertical drilling for coupling with the Pinlock system, as well as for inserting inclined dowels.

- Vertical drilling for the unlocking mechanism.

- Consolidates all assembly functions for the Valinge Pinlock system into a single, efficient solution.

- Increases productivity with high-speed cycles and exceptional flexibility.

- CNC drilling and dowel insertion deliver perfect precision, eliminating errors.

- Simplifies assembly for the end user.

- Ideal for both just-in-time production and large batches, thanks to its minimal cycle time.

- Zero setup time with the ability to handle different boring patterns simultaneously in separate fields.

- Two horizontal drilling units with opposite inclinations for left-hand (LH) and right-hand (RH) panels. Angles adjustable from 42° to 45°.

- Two dowel insertion units with opposite inclinations, also adjustable from 42° to 45°.

- Two inclined vertical drilling units for face drilling with opposite inclinations.

- Three horizontal and three vertical independent drilling units.

- 1300 mm or 2500 mm worktable with four reference points and an indexable central fence.

- Sure Shot revolver system for the fastest cycle times (average of 1 second) and maximum reliability.

- Powerful and user-friendly PC-based Numerical Control.

- Heavy-duty steel frame for maximum stability.

- Large Bakelite table with robust clamps, suitable even for delicate materials.

- Barcode and Ethernet-ready capabilities.

- Optional laser system for part measurement and program generation.

Panel Specifications:

- Length: 20–1300/2500 mm

- Width: 50–∞ mm

- Thickness: 10–60 mm

Additional specifications:

- Installed power: – 15kW

- Compressed air: – 7bar

- Dust extraction hood: – Ø250mm

- Total weight: – 1700 Kg